Research Projects

OPTAVER – Research group optical assembly and connection technology for optical bus systems

| E-Mail: | gerd.hoffmann@ita.uni-hannover.de |

| Year: | 2015 |

| Date: | 28-02-18 |

| Funding: | DFG |

| Duration: | 2015-2021 |

| Is Finished: | yes |

| Further information | www.optaver.de |

The research focus of the sub-project TP1 of the research group OPTAVER is the conditioning of flexible substrates for the application of optical waveguides.

Photonic networks are increasingly used in many industry sectors. They enable an excellent transmission with very large amounts of data. Part of the research project is the low-cost and high-precision manufacturing, as well as the full integration of these systems. Thus, the whole research group OPTAVER deals with the manufacturing of optical bus systems by means of optical assembly and connection technology. The task of the sub-project TP1 is the conditioning of flexible substrates. These form the basis for the optical bus system. Flexographic printing is used for production at the ITA.

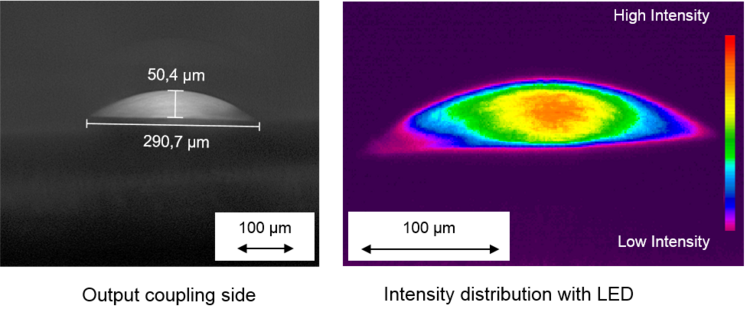

The idea is that by using flexographic printing, the surface properties of flexible substrates can allow for improving the quality of the optical structures generated in downstream processes. In this way, three-dimensional high-definition production can be realized.

Flexographic printing is a high-pressure process which is usually used for the printing of packaging. A printing plate that is clamped onto a cylinder works similarly to a stamp. The projecting structures, which were structured according to the desired print layout, are first wetted with varnish. The subsequent rolling then leaves the desired coating with varnish on the substrate. The possibility of manufacturing electronic circuits by means of printing has recently been examined. In this sub-project, flexographic printing is now used to also explore the realization of optical functions.

Flexographic printing provides the advantage that the process has a very large throughput (up to 15,000 sheets per hour) and thus very low cost per sheet can be realized. Furthermore, flexographic printing machines are also available all over the world in large quantities, so that a proven production process is industrially feasible.

The research focuses on the preparation of surfaces for the realization of optical waveguides, which have a low absorption and meet the requirements of the participating sub-projects. For example, a database is created with relevant measurements of liquid polymers, which are cured with UV light, as well as possible carrier substrates. Also, the way in which high resolution and the desired cross-section shape of the waveguide can be produced is under investigation.

For more information please visit: www.optaver.de.