Research Group: Transport Technology

Additive Manufacturing

-

3D-CopperPrint3D-CopperPrint investigates the use of additive manufacturing (3D printing) for the generation of copper interconnects on adaptive spatial circuit carriers. This process can be used to fabricate hybrid electro-mechanical components as an alternative to existing methods. The approach is based on the application of copper-filled coatings on the surface of three-dimensional objects and the subsequent photothermal laser sintering of the paths.Team:Year: 2018Funding: BMWi, AiF (IGF)Duration: 10/2018 – 06/2020

![]()

Automation Technology

-

Mittelstand 4.0 competence center HannoverThe “Mit uns digital! Das Zentrum für Niedersachsen und Bremen” is the first of eleven centers that are currently being developed throughout Germany to support medium-sized enterprises and craftsmen’s businesses in their digital transformation with well-prepared information, examples and qualification.Year: 2017Funding: Federal Ministry for Economic Affairs and EnergyDuration: 12/15–11/18

![]()

-

DIGITRUBBER - Data mining and AI for optimized cross-process controlAs part of the collaborative project "Digital Rubber Processing - Using Extrusion as an Example" (DIGITRUBBER), an online characterization of the processed rubber compound is being developed by combining new measurement technology approaches, classical modeling and machine learning. This is intended to ensure production at optimum quality while reducing waste.Led by: M. Sc. Sebastian LeineweberYear: 2021Funding: BMBFDuration: 04/2021 – 03/2024

![]()

Industry 4.0

-

SFB 653 - L2: Opto electronic integration of HF communication system for gentelligent componentsThe aim of the sub-project is to integrate the entire communication electronics (high frequency module, microcontroller and memory) in the interior of a workpiece.Year: 2011Funding: DFGDuration: 07/2005 - 06/2017

![]()

-

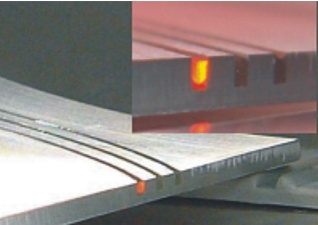

SFB 653 – K1: Dispensed fibers for component-inherent energy transmission and optical signal couplingThe research focus is on the development of a flexible assembly and connection technology for the integration of electronic and optical components in metallic components.Year: 2011Funding: DFGDuration: 07/2005 - 06/2017

![]()

-

Networked, cognitive production systems (netkoPs)Intelligent networking in production – a contribution to the future project Industry 4.0Year: 2013Funding: BMBFDuration: 11/2013 - 01/2017

![]()

-

TRR 123 PlanOS – B01 Offset and inkjet printing of multimode waveguidesHow can optical waveguides be printed? Professors and young researchers from Freiburg and Hanover are trying to answer this question. The sub-project B01 has the task of producing multimodal waveguides for high light output with a width of ten to several hundred microns. The advantages of two printing procedures are used to do so: flexographic printing with high throughput and low cost, and inkjet printing with a large variability and high resolution.Year: 2013Funding: DFG - Transregio 123Duration: 01/2013 - 12/2017

![]()

-

OPTAVER – Research group optical assembly and connection technology for optical bus systemsThe research focus of the sub-project TP1 of the research group OPTAVER is the conditioning of flexible substrates for the application of optical waveguides.Year: 2015Funding: DFGDuration: 2015-2021

![]()

-

LaPOF – Laser active polymer optic fibersThe LaPOF project aims to research technological foundations for innovative laser-active polymer optical fibers as well as their production.Year: 2016Funding: European Regional Development Fund (ERDF)Duration: 12/2016–11/2019

![]()

Optical Technologies

-

HYMNOS – Hybrid Numerical Optical SimulationNumerical methods for the calculation of light distributions in optical media can profit significantly from current trends in computer technology. The aim of this project is therefore the combination of different modeling approaches on different temporal and spatial scales. For this purpose, different aspects from interdisciplinary subject areas in physics and engineering sciences are investigated using models.Year: 2015Funding: Lower SaxonyDuration: 10/2015 – 09/2018

![]()

Optronics

-

OPTAVER – Research group optical assembly and connection technology for optical bus systemsThe research focus of the sub-project TP1 of the research group OPTAVER is the conditioning of flexible substrates for the application of optical waveguides.Year: 2015Funding: DFGDuration: 2015-2021

![]()

-

OptiK-NetThe BMBF project OptiK-Net comprises the possibility of integrating flexible optical conductor structures into the manufacturing process of conventional printed circuit boards in an application- and industry-oriented manner. Optical waveguides in electronic structures are considered difficult to implement in industry, but offer advantages and design possibilities over printed circuit boards with electrical conductor paths. In particular, their high bandwidth and low sensitivity to interference allow new solutions in communication networks. In the OptiK-Net project, obstacles are addressed to enable innovative industrial applications by implementing an exemplary process chain for the manufacture of an optoelectronic rigid-flex printed circuit boards. Within this process chain, two new approaches will be pursued: direct printing of optical waveguides and their direct integration into electrical circuit boards. For the direct printing of optical waveguides, flexographic printing, gravure printing and screen printing are considered as conventional printing processes. These processes enable a high output of similar waveguide structures, so that they can be evaluated with regard to their quality and capability as an industrial process. By integrating them into a rigid-flex composite, the communication of decoupled electrical circuits can be realized.Led by: M. Sc. Andreas EvertzYear: 2019Funding: BMBFDuration: 10/19 - 09/22

![]() © ITA

© ITA

-

3D-multi layer prints of Mechatronic Integrated DevicesIn the 3D-MLD project, additive manufacturing for the generative production of multilayer circuits on spatial components is investigated. The novel approach is based on an alternating coating of the component surface with functional inks and local laser processing. Besides the laser sintering of conductor paths, laser ablation of the insulating coating enables the generation of vertical interconnect accesses in between the layers.Led by: Ejvind OlsenYear: 2021Funding: BMWiDuration: 04/2021 – 03/2023

![]()

Production in Space

-

Setup of an active drop towerAs part of the establishment of the Hannover Institute of Technology (HITec), an active drop tower, the Einstein-Elevator is being set up by the Institute of Transport and Automation Technology (ITA). The design, development and construction of the facility are being carried out in collaboration with the QUEST Leibniz Research School (QUEST-LFS) and the Institute of Quantum Optics (IQ). The aim is to be able to carry out experiments under conditions of microgravity, but also under different partial gravity conditions such as those on the Moon or Mars.Led by: Dipl.-Ing. Christoph LotzYear: 2011Funding: German Research Foundation (DFG) and Lower Saxony state gouvernmentDuration: since 10/2011

![]()

-

Cold Plasma in ZeroGThe height dependence of the plasma conditions and the height dependence of the dynamics of charged microparticles inserted into the plasma are to be investigated in the Einstein-Elevator in a plasma chamber. To this end, the movements of the microparticles during the transition from 1 g to 0 g in the Einstein-Elevator are to be analyzed.Led by: Dr.-Ing. Christoph LotzYear: 2019Funding: German Aerospace Center (DLR)

![]()

-

Experiment carrier for the Einstein-ElevatorAn essential Component of the Einstein Elevator at the Hannover Institute of Technology (HITec) is an experiment carrier, that is used inside the Einstein Elevators gondola. In collaboration with the German Aerospace Center (DLR), the Institute for Transport and Automation Technology is developing a low-vibration carrier. The aim is to use the system to carry out various experiments under microgravity.Led by: M. Sc. Richard SperlingYear: 2020Funding: DLR-SIDuration: 08.2020-07.2023

![]()