Research Projects

TRR 123 PlanOS – A05 Optodic bonding of electro-optically integrated circuits on film substrates

| E-Mail: | yixiao.wang@ita.uni-hannover.de |

| Year: | 2013 |

| Date: | 31-12-17 |

| Funding: | DFG - Transregio 123 |

| Duration: | 01/2013 - 12/2017 |

| Further information | www.transregio123.de |

The long-term goal of the SFB/TRR 123 is to produce optical sources and sinks in the polymer. In the medium term, however, a hybrid solution of semiconductor-based opto-electronic sources and sinks is inevitable due to the high optical performance and reliability resulting from the already sophisticated semiconductor technology. Semiconductor devices will continue to play an important role, in particular as pump sources for lasers in optical films and for the analysis of spectra.

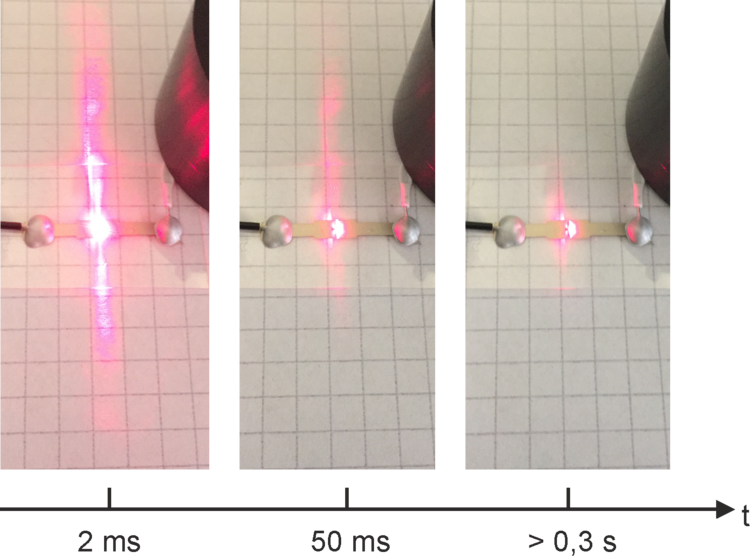

The assembly of chips on films, for example in the area of RFID transponders, is currently state of the art. But this is where heat-curing adhesives are used, which either need very long process times or can be used only on heat-resistant substrates. A possible approach is the use of UV curable adhesives. These are used for mechanical fixing and if possible for the electric contact. The UV light that is required for curing is introduced through the film. The procedure is called “optodic bonding” and developed at the ITA. It enables short processing times without subjecting film or chip to too much heat. Previous procedures achieve mechanical strengths of 20 N/mm² and more, which is also the goal in this project.

Optodic bonding is a cold joining process and represents a novel solution for the joining of opto-electronic components on low-cost polymer films which mostly (e.g. PMMA and PE) have low glass transition temperatures. In addition to the guarantee of mechanical stability, electrical conductivity and thermal stability to be achieved in the bond process, the central question in the optodic bonding process is the production of optical coupling between opto-electronic components and optical fibers. However, the heat dissipation in the subsequent operation of the active opto-electronic components has a significant impact on the performance. This derivation is a basic requirement in order to enable a functional mechanical, electrical and optical performance.

Semiconductor-based LEDs, laser or photodiodes in the wavelength range of 400 nm to 1,100 nm are used for the development and testing of optodic bonding and examined for their suitability for signal transmission.

For more information please visit: www.transregio123.de.