SFB 1153 – A4 Local adaptation of material properties on forming blanks by weld cladding to produce graded hybrid components

| E-Mail: | a.barroi@lzh.de |

| Year: | 2015 |

| Date: | 01-06-19 |

| Funding: | DFG |

| Duration: | 07/2015 – 06/2019 |

| Is Finished: | yes |

| Further information | https://www.sfb1153.uni-hannover.de/ |

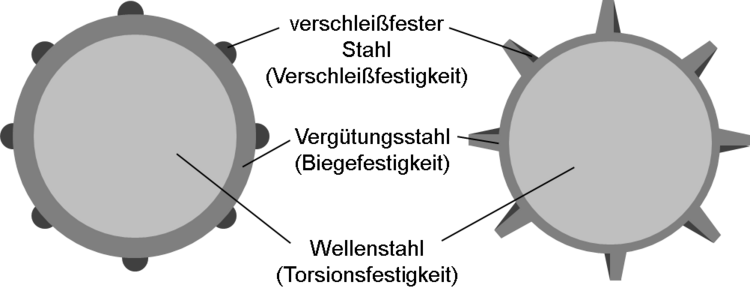

Figure 1: Blank with build-up welded material deposits (left), components molded with newly placed materials (right).

The sub-project is aimed at the manufacture of novel hybrid components from material combinations. This is where local, load-dependent property profiles are imprinted on the components. In order to achieve this, materials are applied to forming blanks by means of build-up welding. The material quantity and position are crucial for the targeted placement of the materials through forming.

Figure 1 represents the vision for the principle of the manufacture of hybrid high-performance components with graded properties, which should be achieved at the end of the SFB. The materials adapted to the load situation by means of welding are deposited on the blank. The positions of the applied materials must be adjusted to the flow behavior during the forming process, as only in this way can the desired positioning in the respective areas be achieved. In the above example of a gear there is particular torsional stress in the core area. The gear tooth root is primarily burdened by bending and the tooth flank is exposed to wear due to contact with a different gear.

In addition to the increased profitability through material-efficient production of high-performance components, the big advantage of this approach is that the material binding of materials through build-up welding on the blank does not mean any adverse properties for the component (e.g. heat-affected zone and welding structure), as the blank is hot forged after welding and only then receives its properties through the forging process as well as the subsequent heat treatment.