VIPlets – Evidence of the aerodynamic potential of riblets produced by grinding and laser removal in a highly loaded axial compressor

| E-Mail: | ludger.overmeyer@ita.uni-hannover.de |

| Year: | 2013 |

| Date: | 30-04-17 |

| Funding: | BMBF – VIP |

| Duration: | 05/2013-04/2017 |

| Is Finished: | yes |

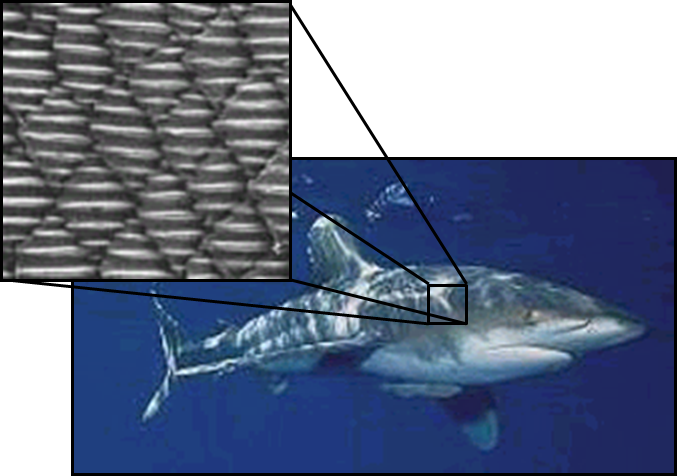

In order to increase the power density and the efficiency in gas turbines and in particular in aircraft engines, minimizing aerodynamic losses remains one of the main targets. An innovative approach to this is the microstructuring of the overflow surfaces of the blading with riblets known from bionics. These small longitudinal riblets can reduce flow losses in the viscous sublayer of the turbulent boundary layer.

In the DFG-sponsored package projects "Riblets for Compressor Blades", the aerodynamic effectiveness of riblets as well as the production-technical manufacturability by grinding and laser ablation were investigated by means of investigations in the lattice wind tunnel of the Leibniz University Hanover (profile loss reduction) and proven on flat plates in the oil channel of the DLR Berlin (wall shear stress reduction).  Based on these results of the basic research, the already existing cooperation in the DFG package projects between the manufacturing institutes IFW (Institute for Production Technology and Machine Tools) and ITA (Institute of Transport and Automation Technology), the Institute for Measurement and Control Technology (IMR), as well as the Institute for Turbomachinery and Fluid Dynamics (TFD), will be able to validate the innovative potential of riblets through the realistic application in a highly loaded axial compressor. The challenges are the adaptation of the design tools developed for use in a two-dimensional flow to the case of three-dimensional flow, which is present in real turbo machines, as well as realizing the economical production of riblets in a combination of grinding and laser ablation on complex 3D blade surfaces. This will require an increase in productivity (area rate) in comparison to the previous production of riblet surfaces under laboratory conditions. Within the scope of this project, this is to be achieved by means of improved methods for structuring the grinding wheels, by developing a method for compensating grinding wheel wear, by beam splitting during laser ablation, and by predictive process assurance.

Based on these results of the basic research, the already existing cooperation in the DFG package projects between the manufacturing institutes IFW (Institute for Production Technology and Machine Tools) and ITA (Institute of Transport and Automation Technology), the Institute for Measurement and Control Technology (IMR), as well as the Institute for Turbomachinery and Fluid Dynamics (TFD), will be able to validate the innovative potential of riblets through the realistic application in a highly loaded axial compressor. The challenges are the adaptation of the design tools developed for use in a two-dimensional flow to the case of three-dimensional flow, which is present in real turbo machines, as well as realizing the economical production of riblets in a combination of grinding and laser ablation on complex 3D blade surfaces. This will require an increase in productivity (area rate) in comparison to the previous production of riblet surfaces under laboratory conditions. Within the scope of this project, this is to be achieved by means of improved methods for structuring the grinding wheels, by developing a method for compensating grinding wheel wear, by beam splitting during laser ablation, and by predictive process assurance.